Fire Rated Cladding

The use of fire resistant materials, particularly fire rated cladding, within specification has remained an important consideration for many years, with the overarching goal to reduce the risk to people and property if there was a fire.

UK construction and design professionals need to consider how to control or restrict the spread of a fire to maintain the fire resistance of the building. This is notably relevant for the manufacture of cladding, either as part of a new build construction or a refurbishment project to replace cladding that is deemed unsafe and unfit for purpose.

As such, fire rated cladding is essential for the safety of a building’s occupants.

Knotwood aluminium wood effect cladding is fire rated to A2-s1-d0 and classed as non combustable. This ensures it is an excellent solution for architects, main contractors and developers who are specifying cladding for commercial or residential building applications over 11m in height, or any project where an A2 fire rating is required by law.

For specification guidance and product samples, contact our team today.

Fire rated cladding for your project

The purpose of cladding can vary from practical specifications such as increasing thermal energy or providing weather protection, to improving the aesthetics of a building. One factor that remains constant throughout any specification is ensuring the cladding carries suitable fire rating properties.

On November 29, 2018, the government issued regulations that went into effect on December 21, 2018, prohibiting the use of combustible materials in and on the external walls of buildings 11 metres or taller that contain one or more dwellings.

As a result, the use of combustible materials, such as certain types of cladding, has been restricted in order to improve the safety of high-rise buildings in the UK. The regulations specify that all new buildings falling under the scope of the ban must use materials that are either non-combustible or have limited combustibility.

Many external cladding solutions available to UK design professionals carry a minimum classification of surface spread of flame, which is designed to control and slow down the spread of fire. However, there is increasing importance now to specify fire resistant cladding which provides higher classifications of limited or non-combustibility.

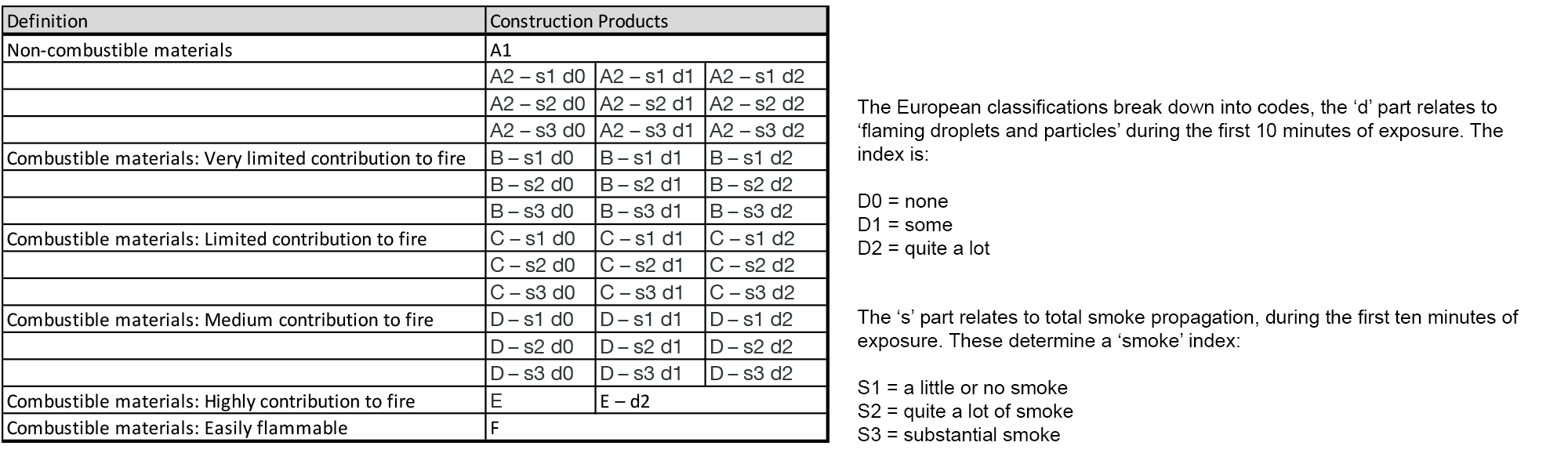

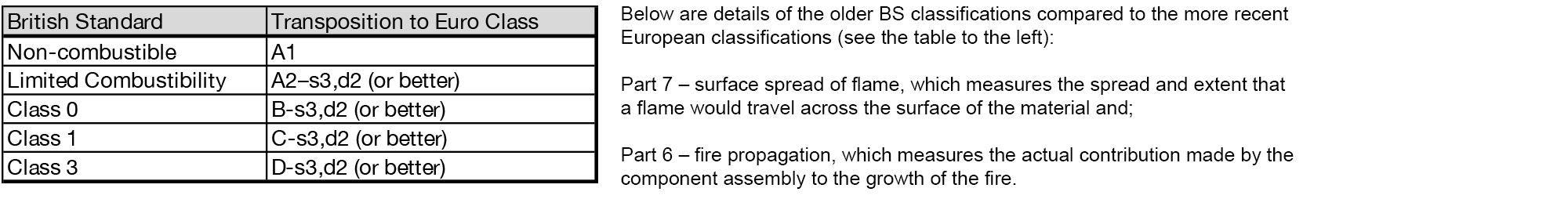

Such cladding panels carry a fire classification result ranging from A1 to D in accordance with European Standards EN-13501-1.

Various factors come into play in all fire safety standards that include heat transmission, flame spread, smoke production and flaming particle emissions, not just what happens if a direct flame is applied.

When considering fire rated cladding for your project, you should be confident that your cladding system is fit for use and backed by relevant fire test data. Please see the table below which gives a further understanding of the fire classifications:

A solution for cladding refurbishment projects

When it comes to refurbishment projects, cladding can offer a range of benefits.

- It can be used to cover imperfections and therefore improve the overall aesthetic of a building

- Cladding can provide exceptional thermal insulation which reduces carbon footprint

- Sufficiently fire rated cladding can protect a building from the spread of fire

- Cladding protects a building from weather damage and erosion

Cladding refurbishment projects are often more sustainable, cost-effective, and quicker to complete, compared with replacing a building with a completely new structure.

Architects have confidence that by specifying Knotwood’s cladding system for refurbishment projects, they are working with cladding that is:

- Non-combustible: Backed by relevant fire test data. All systems are EN 13501-1 Class A Fire rated.

- Seamless and flexible: The panels are incredibly versatile with a huge range of customisation, enabling for unique and intricate designs.

- Non-warping: Cladding installations will stand the test of time and won’t deteriorate or warp.

For main contractors and developers, working with Knotwood’s cladding system means:

- Time-saving: Over-cladding an existing building is a cost-effective way of returning it to its former glory.

- Durable and lightweight: The cladding is weather and scratch resistant as it is made of aluminium, also being easy to work with due to its light weight properties.

- Low maintenance: The aluminium profiles will be easy to maintain for years to come.

Knotwood – premium wood effect aluminium cladding

Knotwood’s premium wood effect aluminium cladding offers a beautiful timber look that is characterful and aesthetically pleasing, yet it’s robust and durable.

Aluminium is notoriously strong and lightweight, making it a suitable product to specify for external cladding for commercial and residential builds.

These elements make it the perfect material for cladding, soffits, decking and other applications. Wood effect aluminium has become more popular for both residential and commercial buildings because of its on-trend aesthetic, sustainability and nett carbon attributes, weather resistance and versatility.

It is non-warping and has colour stability that withstands the most extreme environments; both features give designers and developers the confidence that using Knotwood aluminium wood effect cladding won’t risk the longevity of the building design.

Installation of Knotwood cladding for both internal and external projects is made easier by the light weight of the aluminium, particularly when compared to wood alternatives. This makes it particularly versatile which is ideal for unique and intricate designs.

Regardless of how tough environmental conditions might be, Knotwood is weather resistant, so it won’t swell, grow mould or rust. It is also impervious to termites and ants so doesn’t require chemical treatment for protection against pests, and is scratch resistant thanks to the topcoat of exterior grade paint that is baked on to provide resistance to chipping, flaking, blistering and scratching.

FAQs

How does the Knotwood cladding system work?

Knotwood cladding is based on an interlocking board system. Each board has a 5mm adjustable spacing which reduces waste through minimal cutting.

Is Knotwood fire rated cladding eco-friendly?

Yes. We use VOC free (Volatile Organic Compounds) coatings and lead-free finishes. The product is also 100% recyclable at the end of its lifespan.

Does Knotwood require much maintenance?

No. Our specialised finishes have outstanding properties that ensure ease of maintenance and longevity of surfaces.

What is the fire rating and safety standard compliance of Knotwood’s aluminium wood effect cladding for commercial and residential building applications?

Knotwood aluminium wood look cladding is non-combustible and has a fire rating of A2-s1-d0. This ensures that it is an excellent choice for architects, general contractors, and developers specifying cladding for commercial or residential building applications exceeding 11 metres in height, as well as any project requiring a fire rating of A2.

Choose Knotwood fire rated cladding for your project

For more information on the fire testing of Knotwood fire rated cladding, or for any other enquiries about our premium wood effect aluminium cladding, please get in touch with the team using our online form or by calling 0800 131 6165.