An important CWCT cladding test pass for Knotwood

Knotwood’s aluminium wood-effect cladding has passed rigorous CWCT testing (Centre for Window and Cladding Technology). CWCT is an industry-respected publisher of standards and guidance on the performance of building envelopes, facades, cladding and glazing.

- For Knotwood, passing CWCT testing validates the performance, safety and integrity of our cladding. The cladding had been previously tested in Australia and USA, but not to CWCT standards.

- For architects and designers, successful CWCT testing is a green light for specifying our products with confidence, knowing that they are certified as safe.

- For homeowners, Knotwood’s CWCT test result gives them the assurance that their cladding offers excellent performance without safety concerns.

What is CWCT testing?

CWCT testing lasts for the lifetime of the product, or until regulations change. CWCT set performance standards for the weathertightness of building envelopes, covering:

- Wind resistance serviceability

- Wind resistance safety

- Watertightness (dynamic and static)

- Soft body impact

- Hard body impact

CWCT tests determine the serviceability of the cladding when subjected to wet and windy weather conditions, as well as impact by soft and hard objects. Aspects such as the maximum air pressure reached, and the extent of damage caused by impact, form part of the test results.

The CWCT standard for systemised building envelopes holds significant sway in construction, making a pass in testing an influential factor in specification decisions for architects. The National Building Specification (NBS) and National House Building Council (NHBC) have both adopted the CWCT standard.

CWCT testing can only be carried out at approved, specialist centres that are equipped to facilitate the necessary setup and testing procedures. These centres are regularly assessed by CWCT to ensure they continue to comply with their standards.

The CWCT testing process

Wind resistance (serviceability and safety)

To test wind resistance serviceability, dynamic pressure is applied to the sample by pumping in and sucking out air within a sealed chamber. All gaps and modules are sealed to create an airtight surface. If any gaps open during the test, this indicates a fault in the system.

To test safety, wind resistance is tested to 2400 pascals (units of pressure) and then up to 3600 pascals by applying pressure to stress-test all areas of the cladding system, including rails and fixings.

Watertightness (dynamic pressure)

An aeroplane engine blasts 600 pascals of water onto the surface which is the equivalent of a hurricane to see if water can be forced into the panels. If it can, the cladding has failed the test.

Impact resistance (hard and soft impact testing)

A solid steel ball is swung at the surface for hard impact resistance testing, while for soft impact testing a 50kg leather bag of glass spheres is swung at the surface from a range of distances.

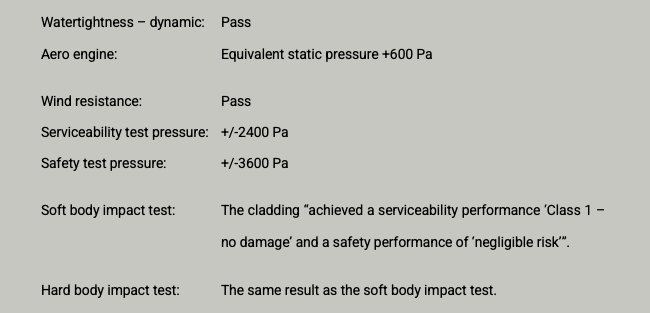

Knotwood’s CWCT test results

Knotwood samples sent for testing were the 200, 150 and 100mm wide profiles, all interlocking with a 5mm shadow gap and powder coated wood grain effect.

Here are some of the highlights of our test report:

Why CWCT testing matters to Knotwood

At Knotwood we are keen to continually test our products to the highest industry standards. Safety is paramount in the specification of products in the built environment. A CWCT certificate tells an architect, property developer or homeowner that our cladding is the ideal, safe application for their properties.

Choose Knotwood for your wood-effect, aluminium cladding

It’s not wood, It’s aluminium. Lighter, stronger, straighter than real wood.

For more information on Knotwood’s CWCT tested aluminium cladding, please get in touch.